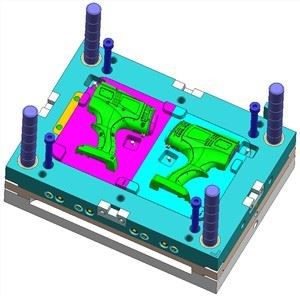

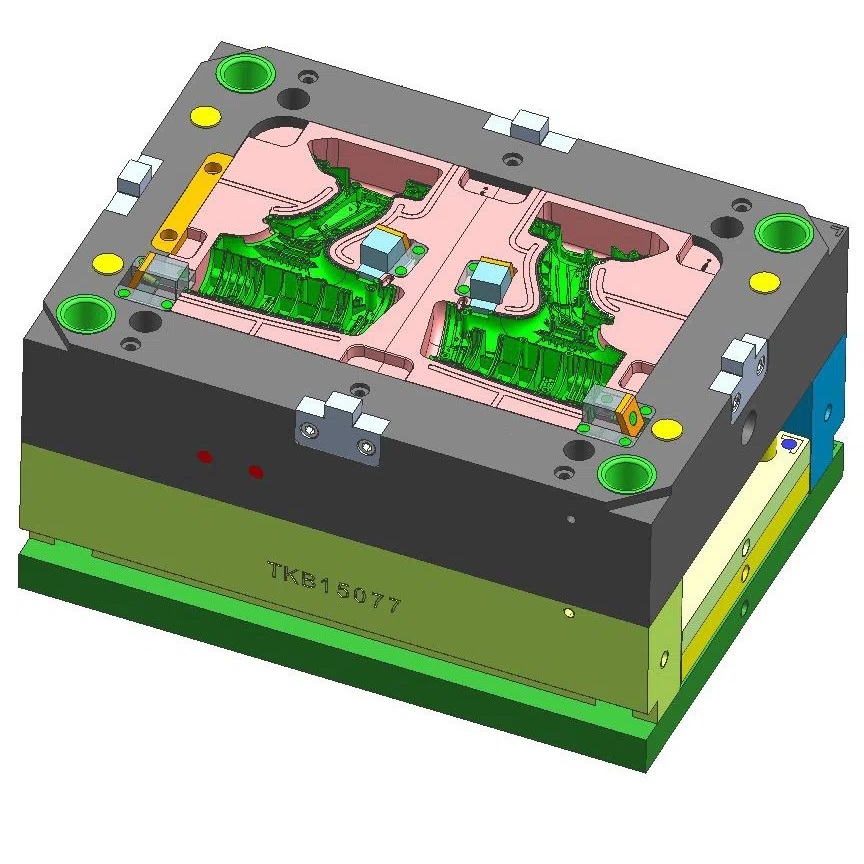

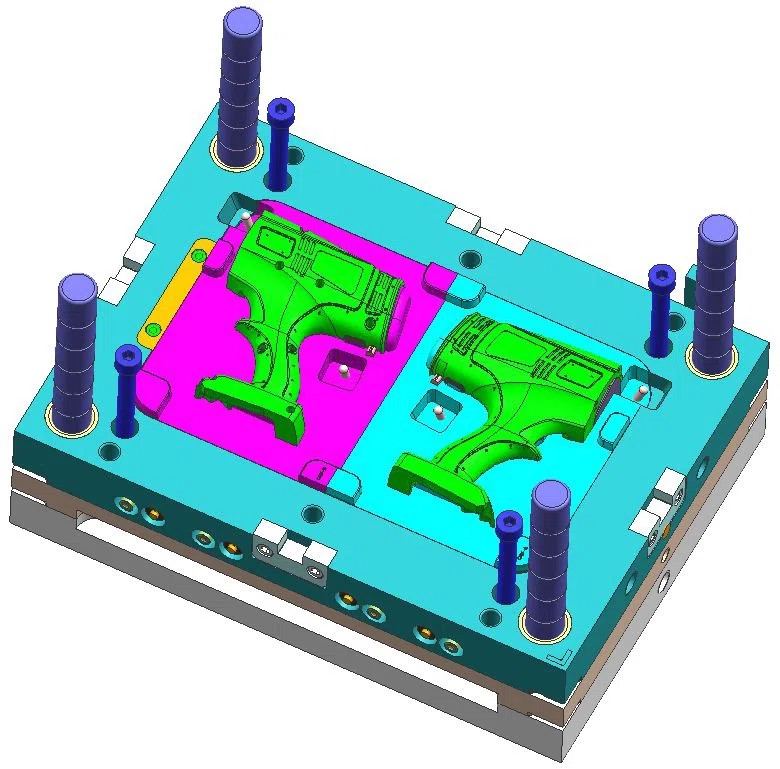

Injection Molding Mold Design

Short Description:

JS MOULD Mold has a rich experienced injection molding tool design team—one that knows how to minimize expenses involved in the tool design and manufacturing process while producing parts of high quality—can mean the difference between success and failure for your project. JS MOULD Mold is an industry…

JS MOULD Mold has a rich experienced injection molding tool design team—one that knows how to minimize expenses involved in the tool design and manufacturing process while producing parts of high quality—can mean the difference between success and failure for your project. JS MOULD Mold is an industry leader in injection molding mold design engineering and manufacturing.

JS MOULD Mold’s team of engineers will optimize the mold design and selected material for injection molding to ensure that a suitable product can be manufactured.

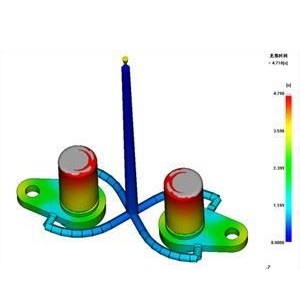

Once the product design is approved, we move on to generating the molding design, making sure the mold flow analysis is optimal. We offer quick turnaround and maximum versatility by building your plastic injection mold tooling either in-house . Additionally, on-site repair and maintenance of customer tooling eliminates the distractions and inefficient processing that commonly result from the use of outside vendors.JS MOULD Mold provides turnkey solutions for businesses that need world-class injection mold tooling. Feel free to contact us if you have questions about our plastic injection mold design and manufacturing services that are not answered in this section.

CAPABILITIES INCLUDE:

• Injection Mold Design

• Rapid Prototyping

• Precision CNC Machining

• Injection Mold Manufacturing

• Plastic injection molding

•Assembling and Decoration